Fuelpower Soot Remover Liquid Plus

Newly formulated Unitor™ FuelPower™ Soot Remover Liquid Plus increases the cleaning/maintenance interval for your exhaust gas economizer/boiler from every 3 months to 12–15 months.

Extensive yearlong trials on MV Tonsberg, a 76500 GRT Ro-Ro vessel propelled by MAN B&W 7 Cylinder L70 ME-C8, clearly showed tangible benefits of using our new treatment chemical. The use of our new Unitor™ FuelPower™ Soot Remover Liquid Plus provides clear benefits:

- Keeps EGB free of soot

- Increases cleaning interval to 12-15 months

- Prevents acid formation

- Prevents cold corrosion

- Reduces risk of soot fires

- Environmentally friendly by reducing emission of soot particles

- Reduces the challenge of dealing with the acidic wash water every 3 months

- Absence of heavy metal compounds such as copper nitrate

- 24/7 support for your needs

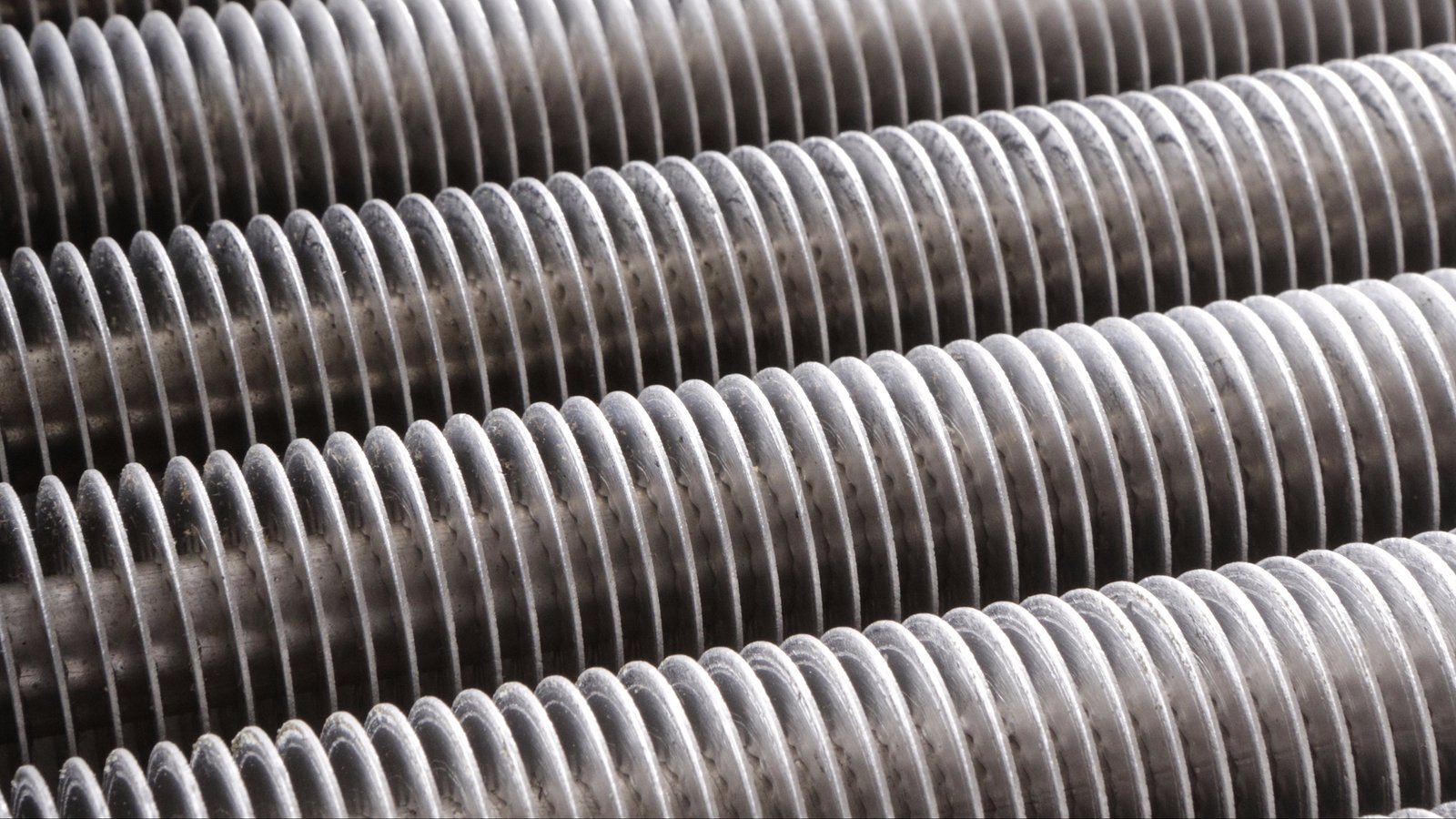

CHALLENGES WITH SOOT DEPOSIT

Operational

- Untreated fuel oil leads to frequent cleaning, every 2-3 months interval

- Using additional time, money and resources to carry out a cleaning job when vessel is in port, additional strain on resources

- Wear and tear of equipment and labour needed to carry out the cleaning

Environmental

- Challenge of discharging the dirty wash water as it contains acidic soot that cannot be disposed directly into sea water, requiring additional waste management

Equipment:

- Reduced efficiency as soot deposits are extremely insulating - just a 1mm layer of soot can cut the efficiency of the exhaust gas boiler by up to 10%

- Soot fires result in overheating due to soot deposit

- Cold corrosion in case of slow steaming with low exhaust temperatures

INHERENT CHALLENGES IN INDUSTRY

Low-quality fuel

- Contaminants such as vanadium, sodium, aluminium, silica, potassium and other metals can cause incomplete combustion

Design of exhaust gas boiler

- Incorporation of low velocity flue gas for higher efficiency may result in higher soot deposit

Operational

- Reduction in exhaust gas temperature from modern engines and slow-steaming practices increases the tendency for deposit formation or cold corrosion in the exhaust gas boiler

PRODUCT DETAILS: